The price of automotive electronic products is generally more expensive, because its internal components and parts have strict vehicle regulations on various indicators such as operating temperature. So what are the strict requirements for car-regulated products?

1. Working environment

We know that electronic products are usually divided into the following categories according to working standards

Consumer grade: -10—60℃/-20—70℃

Industrial grade: -30—85℃/-40—85℃

Automotive grade: -40—105°C/-40—125°C

Military level: -40—150℃/-55—155℃

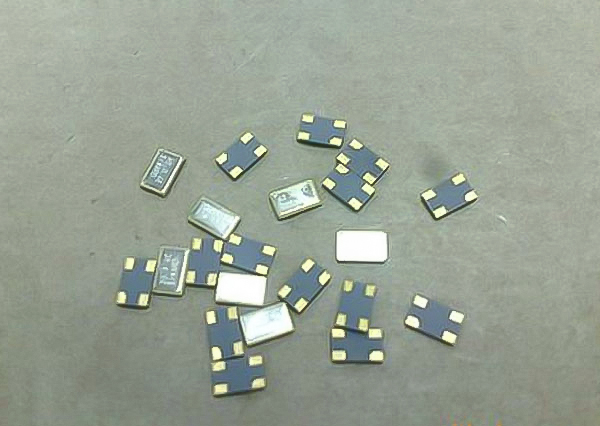

It should be noted that the military grade is mainly reflected in the limit index, but the power consumption is often higher than that of commercial and civilian use. In addition, it is also reflected in the workmanship. It’s not that the electronic products used in cars require the specified car level. According to reports, there are as many as 200 quartz crystals used in a car, which are distributed in different parts of the car. I think that the engine part of the engine has extremely strict requirements on the working temperature of the crystal oscillator, the working temperature must meet -40-125℃, or -40-150℃; audio, navigation and other systems do not have very high indicators for the working temperature range, -40-85 ℃, or -40-105℃ can satisfy.

2. Comply with AEC standard

AEC Q100 for active components

AEC Q200 for passive components

For some components that have not been approved by the AEC standard, many component manufacturers will find some third-party organizations such as CNAS to certify. It is difficult for testing organizations to spend a lot of energy to understand the product characteristics of all components. In the automotive supply chain, these certifications from third-party organizations cannot gain the trust of professional vehicle manufacturers or component suppliers.

3. Vibration and shock resistance

The car works in a sporty environment. For different models of car-grade crystal oscillators, the level of vibration and shock requirements will be much higher than that of consumer electronic products. NDK crystal oscillator (Nippon Denpa Kogyo Co., Ltd.) is currently a crystal oscillator manufacturer with a wide market share in the automotive electronics field, and enjoys a high reputation and reputation in the industry. The car-grade crystal oscillator produced has excellent environmental resistance characteristics such as heat resistance, vibration resistance, and impact resistance; it can also exert stable vibration characteristics under extremely harsh environmental conditions; meets the reflow temperature curve requirements of lead-free soldering; conforms to AEC- Q200 standard.

Fourth, reliability

Design life: The general design life of a car is about 15 years and 20W kilometers, and the life requirements of automotive-grade components cannot be lower than the design life of the car; under the same reliability requirements, the more components and links the system consists of, The higher the reliability requirements of the components. The requirements of auto parts are usually described in PPM (parts per million).

Five, manufacturing process

In order to achieve temperature differences among consumer, industrial, and automotive grades, different materials and even different processes are often used. For example, consumer and industrial grades are packaged with plastic or resin, and automotive grades are packaged with ceramics. What are the excellent characteristics of ceramic packaged crystal oscillators:

1. Good moisture resistance, not easy to produce micro-cracking phenomenon;

2. There is no damage after thermal shock test and temperature cycling test, and the mechanical strength is high;

3. The coefficient of thermal expansion is small, and the thermal conductivity is high;

4. Good insulation and airtightness, the chip and circuit are not affected by the surrounding environment, and more importantly, its airtightness meets the high requirements of high sealing;

5. Good light-proof, can effectively shield visible light and excellent reflection of infrared rays, and can also meet the low reflection requirements of optical-related products.